As today’s supply chains become increasing complex and volatile, having a sophisticated load planning solution is no longer an option – it’s a necessity. Embarkation specialists are constantly challenged with last-minute cargo changes, and they must respond quickly and efficiently to meet schedules and keep costs down.

As today’s supply chains become increasing complex and volatile, having a sophisticated load planning solution is no longer an option – it’s a necessity. Embarkation specialists are constantly challenged with last-minute cargo changes, and they must respond quickly and efficiently to meet schedules and keep costs down.

However, without an automated system in place, logistics personnel must painstakingly re-calculate the balance, distribution and loading sequence for the cargo stowage. This laborious, manual process can result in costly delays and wreak havoc on the bottom line.

Tapestry Solutions, a Boeing Company, has addressed these challenges with the Integrated Computerized Deployment System (ICODES) and its commercial derivative, GOLDesp Load Planner. In the process, Tapestry’s customers are saving millions annually.

WHAT IS ICODES?

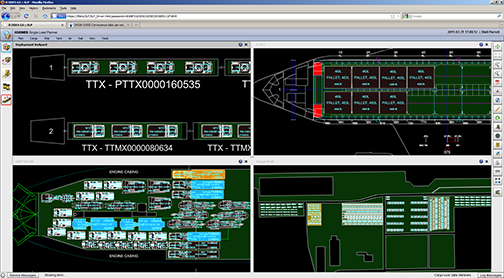

ICODES – designated as the Single Load Planning Capability (SLPC) for the U.S. Department of Defense (DoD) – is an intelligent software platform that provides near real-time planning and tracking of cargo stowage for ships, aircraft, railcars, trucks and yards.

ICODES automates processes for multimodal load planning, ensures better space utilization, and improves supply chain performance in support of the military’s deployment and distribution operations.

ICODES automates processes for multimodal load planning, ensures better space utilization, and improves supply chain performance in support of the military’s deployment and distribution operations.

ICODES interfaces with multiple cargo documentation systems, allowing users to easily exchange and interpret global cargo movement plans throughout the enterprise. ICODES also sends alerts that notify users of violations in a load plan or estimation. In addition, ICODES optimizes logistics operations for the day-to-day management of transportation terminals, and provides predictive analysis for future operations.

In the detailed description below, learn why ICODES has served as the U.S. military’s #1 load planning platform for decades –and how the same technology is assisting Tapestry’s commercial customers today.

THE SUPPLY CHAIN CHALLENGE

Transporting military assets involves moving a vast amount of cargo around the globe – everything from vehicles, weapon systems,  ammunition to communication assets, fuel and food supplies – by land, air and sea. It also involves the staging of military personnel.

ammunition to communication assets, fuel and food supplies – by land, air and sea. It also involves the staging of military personnel.

Managing all the variables is extremely complex in the theater of war. Logistics personnel face uncertainty, threats and information saturation on a daily basis. The load planning process typically involves several modes of transportation, last-minute cargo changes and hazardous conditions.

With continuous information changes and problems that arise, commanders need access to timely and accurate information – actionable data they can easily understand – as well as complete situational awareness.

Decision-makers require a transportation management solution that provides in-transit visibility, speed, extensive documentation accuracy, security, and above all else, automatic reasoning and analysis capabilities.

In the commercial domain, shippers also require supply chain visibility and automation to meet the demands of their customers. Elsewhere in the private sector, other entities have increasingly rigorous lifecycle requirements beyond, but closely related to, shipping – tracking parts and completing other tasks.

A FRAMEWORK FOR MILITARY LOADING AND MORE

ICODES provides the military with a flexible, modular, load planning solution that features automatic reasoning and analysis capabilities. Built with intelligent software agents, ICODES has provided the framework for U.S. military load planning operations for over 20 years.

ICODES first became the system of record for the U.S. Army’s ship load planning operations in 1997, and by 2001, the U.S. Marine Corps came onboard. The U.S. Air Force adopted ICODES in 2015, and in parallel, the functionality of ICODES progressively widened to include rail and then aircraft.

ICODES first became the system of record for the U.S. Army’s ship load planning operations in 1997, and by 2001, the U.S. Marine Corps came onboard. The U.S. Air Force adopted ICODES in 2015, and in parallel, the functionality of ICODES progressively widened to include rail and then aircraft.

Today, ICODES serves as the DoD’s joint program of record for multimodal (air, ship, rail and truck) global deployments. Approximately 25,000 U.S. military user accounts around the globe have access to ICODES.

ICODES remains responsive to the dynamic logistics environment for its end users today, and continues to evolve to meet user requirements well beyond this decade. Recent enhancements include the delivery of an Initial Operational Capability for a Sea Service Deployment Module (SSDM) for ICODES software v7.1. The SSDM enhancement provides the U.S. Navy and Marine Air-Ground Task Force (MAGTF) with a common operating picture for managing cargo and personnel movements via ICODES.

THE RETURN ON INVESTMENT

With ICODES technology, Tapestry calculates that the U.S. defense department is achieving annual sustainment cost savings of more than $10 million annually. These  efficiencies are derived from its Service Oriented Architecture (SOA) environment, as well as its internal knowledge-base, intelligent software agents, and the automation of load planning task sequences.

efficiencies are derived from its Service Oriented Architecture (SOA) environment, as well as its internal knowledge-base, intelligent software agents, and the automation of load planning task sequences.

As a result, ICODES has reduced the time to prepare load plans by 50% or more. In addition, users have access to myriad capabilities – all on a single platform – made possible with the SOA environment design principles (e.g., its standard API and “reusable” services).

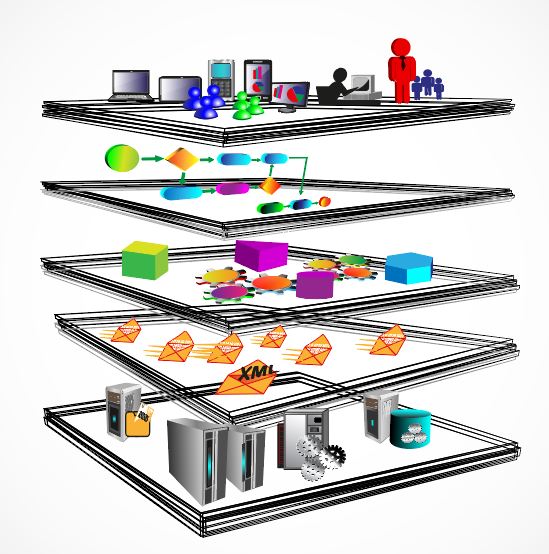

The SOA infrastructure provides a highly modular, flexible platform that allows users to easily add new web applications and services, including legacy applications. This agile architecture provides a cost-effective way to add new capabilities to an enterprise-level system, for instance, without causing disruption to existing business processes within the system.

COMMERCIAL APPLICATIONS

Encouraged by U.S. military’s returns on investment, ICODES technology has further been delivered to non-DoD customers as GOLDesp Load Planner and GOLDesp Terminal Manager commercial variants. Customers include the Royal Australian Navy, Royal Australian Air  Force, Lithuania and NATO (Hungary) and Heavy Airlift Wing. These two commercial modules, which are fully compatible with ICODES, will be also be

Force, Lithuania and NATO (Hungary) and Heavy Airlift Wing. These two commercial modules, which are fully compatible with ICODES, will be also be  delivered to other nations’ defense forces over the next few months.

delivered to other nations’ defense forces over the next few months.

Tapestry’s customer base for non-defense operations is also diverse and expanding. In the public sector, the U.S. National Science Foundation has used the Load Planner tool in support of its Antarctica exploratory missions, enabling customized load planning for “routine” to the most challenging operational conditions requiring landing on sea-ice runways.

Other commercial entities that use the ICODES commercial modules include Wilhelmsen, Höegh Autoliners, Pasha Group, Liberty Global Logistics, SEACOR Holdings (previously as International Shipholding Corp.) and Logistics Management Institute.

The commercial customers use the technology to transport both commercial and military shipments, including cargo for U.S. DoD and international militaries.

THE TECHNOLOGY FOUNDATIONS

ICODES delivers six, high-level, functional capabilities to the customer. This suite of logistics services permit individuals in the logistics chain to intricately manage load planning, and successfully complete higher-order requirements up through managing ports, rail heads and other logistic nodes.

Artificial intelligence, in the form of embedded knowledge-based and rule-based agents, increase the speed, accuracy and quality of ICODES’ deployment operations.

Artificial intelligence, in the form of embedded knowledge-based and rule-based agents, increase the speed, accuracy and quality of ICODES’ deployment operations.

Supply chains in the defense and commercial sectors also take advantage of SOA technology to complete lower-level, foundational capabilities, or micro services (services) for every requirement.

Combining these services within the SOA environment not only allows a system to execute highly complex computational tasks, but also extends the lifecycle of legacy systems. This, in turn, fills in functional gaps tailored to specific capabilities, allowing business processes to evolve.

A TEMPLATE FOR GROWTH

Current defense and commercial customers have further benefited from ICODES’ SOA infrastructure, which is made up of loosely coupled “services” that are somewhat related but can also work independently to manage processes. Its layered architecture is similar to the concept of LEGO blocks, allowing users to cost-effectively add functionality and easily evolve business processes.

This construct is permitting Tapestry’s development team to reuse existing functionalities, for example, and transition five legacy systems  into a Cloud-compatible, Web application-based solution.

into a Cloud-compatible, Web application-based solution.

The implications of service reusability is significant for prospective commercial and other customers, regardless of their annual sales volume, or other metric of size. Rather than buy new off-the-shelf software, the end users can use service-oriented blocks in ICODES’ architecture to build “new” tailored software, scaled to their requirements.

With this feature, customers achieve greater flexibility, reduced development time and other costs, as well as increased system stability.

In one example of the state-of-possible, Tapestry’s engineering team built a software interface – from storyboarding through testing and fielding – and integrated a legacy system into ICODES in only 60 days.

Tapestry’s competencies in building software interfaces are well established, with approximately 25 interfaces supported by ICODES. The applications within ICODES include the Single Load Planner, Conveyance Estimator, Conveyance Builder, Data Manager, Data Cleanser, Conveyance Repository, Hand-Held Terminal Administrator, Information Repository, Breakbulk Tool, and more.

FUTURE ENHANCEMENTS & OPPORTUNITIES

Tapestry Solutions is focused on helping current and prospective customers keep supply chain costs down and gain other efficiencies through concurrent program and technology enhancements.

Tapestry Solutions is focused on helping current and prospective customers keep supply chain costs down and gain other efficiencies through concurrent program and technology enhancements.

The DoD has contracted with Tapestry Solutions to redesign particular, remaining legacy logistics applications to become services-capable and link into ICODES’ SOA infrastructure – the Collaborative Information Workspace (CIW).

Beyond these programmatic advancements, future ICODES technology enhancements will leverage Tapestry’s competencies in RFID and its Enterprise Sensor Integration (ESI) solution, which in turn, will become part of the SOA infrastructure.

Tapestry Solutions is further staying ahead of customers’ imminent migration to Cloud providers for computational and data storage purposes via research and development programs, including an effort involving a commercial sector, Cloud service provider.

In addition, Tapestry is refining other capabilities in the service-client architecture environment, including options as a software-as-a-service (SaaS) platform. An SaaS capability may conceptually provide military and commercial customers a “fee-for-service” or “pay-as-you-go” business model for ICODES/GOLDesp Load Planner access.

This technology thrust will further allow Tapestry Solution to move beyond the current ICODES program model of issuing quarterly, annual and other long-lead version upgrades, and be more continuously responsive (in weeks, or possibly days) to a customer’s change requests.

And finally, ICODES is transitioning from its Flash multimedia, software platform to the emerging Hyper Text Markup Language (HTML) 5 format. This technology enhancement will streamline the server-to-client data exchange, allowing ICODES customers to run the latest version of the system on even “older” hardware – with a Web-browser required.

With these emerging and existing technologies, ICODES/GOLDesp Load Planner tools are designed to improve the efficiency and effectiveness of load planning operations for years to come. To learn more, contact Tapestry for consultation or email tapestrymarketing@boeing.com

The appearance of U.S. Department of Defense (DoD) visual information

does not imply or constitute DoD endorsement.

Contact:

Janet Dayton

Tapestry Solutions Inc.

Boeing Global Services

tapestrymarketing@boeing.com

Faced with budget cuts and a shortage of spare parts, military forces often resort to the inefficient maintenance practice of cannibalization – a strategy in which serviceable parts are removed from one complex asset to satisfy the operational needs of another higher-priority asset.

Faced with budget cuts and a shortage of spare parts, military forces often resort to the inefficient maintenance practice of cannibalization – a strategy in which serviceable parts are removed from one complex asset to satisfy the operational needs of another higher-priority asset.

quality inspection is required for the removed part. This significantly increases personnel labor hours and costs.

quality inspection is required for the removed part. This significantly increases personnel labor hours and costs.

ESI ensures all IT systems are interoperable, enabling the military to leverage the full potential of the IoT. It ensures standardization across the enterprise, allowing asset management and tracking systems to talk to each other in the larger IoT ecosystem.

ESI ensures all IT systems are interoperable, enabling the military to leverage the full potential of the IoT. It ensures standardization across the enterprise, allowing asset management and tracking systems to talk to each other in the larger IoT ecosystem. Streamlining logistics and procurement in the age of joint operations,” Tapestry’s speaker outlined best practices in information technology for achieving coalition interoperability, with references to the company’s Maintenance, Repair and Overhaul (MRO) software solution. GOLDesp is also featured in Tapestry’s booth at the Kuwait conference, which is supported by the newly formed Armament and Procurement Authority of the Kuwait Ministry of Defence.

Streamlining logistics and procurement in the age of joint operations,” Tapestry’s speaker outlined best practices in information technology for achieving coalition interoperability, with references to the company’s Maintenance, Repair and Overhaul (MRO) software solution. GOLDesp is also featured in Tapestry’s booth at the Kuwait conference, which is supported by the newly formed Armament and Procurement Authority of the Kuwait Ministry of Defence.