Tapestry Solutions, a Boeing company [NYSE: BA], today announced it will provide ongoing sustainment support for the U.S. Transportation Command’s (USTRANSCOM) Single Mobility System (SMS)/Coalition Mobility System (CMS) under a subcontract agreement with Kforce Government Solutions, Inc. (KGS). USTRANSCOM awarded the contract to KGS through the U.S. Department of Veterans Affairs’ VA T4NG contract vehicle.

System (SMS)/Coalition Mobility System (CMS) under a subcontract agreement with Kforce Government Solutions, Inc. (KGS). USTRANSCOM awarded the contract to KGS through the U.S. Department of Veterans Affairs’ VA T4NG contract vehicle.

SMS is the primary Command-and-Control (C2) system that provides aggregated tracking and visibility for all U.S. military cargo and passenger movements over land, air and sea. With over 20,000 user accounts worldwide, the enterprise system enables personnel to view requirements, plan missions and track execution for real-world mobility operations and contingency/exercise planning. The CMS application supports coalition operations, providing situational awareness, collaboration and rapid coordination for coalition movements by aircraft, ship, rail and road.

U.S. Navy photo by Grady T. Fontana / Released

Tapestry Solutions, the developer, has supported the SMS/CMS program since its inception. Under the contract, Tapestry will continue to provide critical engineering and development services, including migration to cloud-based services, in collaboration with the KGS team.

“We are proud to play a major role in the development and modernization of SMS – a critical technology that has served as the entry point for the defense transportation system for nearly 20 years. We look forward to continuing our important work as a member of the KGS team,” said Robin Wright, President & CEO, Tapestry Solutions “Our team combines the best of Tapestry’s deep domain experience – and years of success supporting USTRANSCOM programs – with the KGS team’s diverse IT technologies and services.”

About Tapestry Solutions

Tapestry Solutions, Inc. is a global provider of information management software and services for defense, government and commercial markets. We provide mission planning, training and simulation support to maximize readiness for our warfighters. We also help solve logistics challenges for the world’s largest and most complex supply chains. Supporting customers from more than 50 locations worldwide, Tapestry Solutions is part of Boeing Global Services.

Operating as one of Boeing’s three business units, Global Services is headquartered in the Dallas area. For more information, visit www.boeing.com/services.

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.

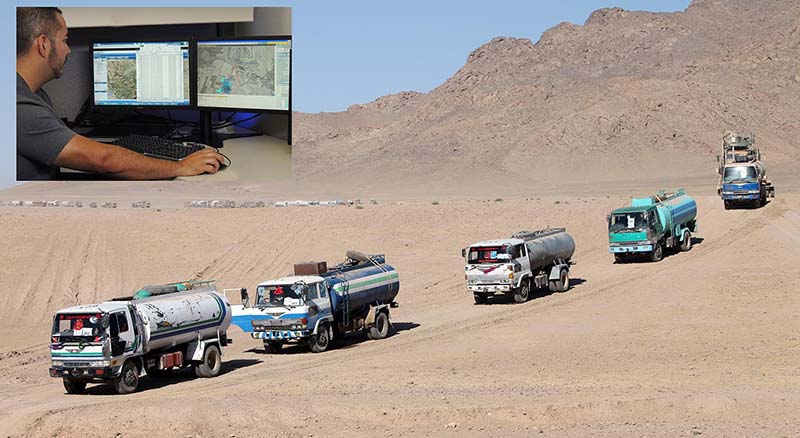

GDMS acts as a central data fusion system that enables the U.S. military to have near real-time visibility, tracking metrics and accountability for all registered commercial vehicles. At the core of GDMS is a centralized database that links cargo movements with vehicles equipped with GPS-based transponders. The system provides panic alarms/alerts to contractors as they pass hazards and checkpoints, and displays the mission data on topographical maps. The system includes instant replay functions that allow for course-of-action analysis.

GDMS acts as a central data fusion system that enables the U.S. military to have near real-time visibility, tracking metrics and accountability for all registered commercial vehicles. At the core of GDMS is a centralized database that links cargo movements with vehicles equipped with GPS-based transponders. The system provides panic alarms/alerts to contractors as they pass hazards and checkpoints, and displays the mission data on topographical maps. The system includes instant replay functions that allow for course-of-action analysis. consumers’ spending habits, behaviors and more.

consumers’ spending habits, behaviors and more.

In one year alone, over 2.4 million pieces of equipment worth a total of $250 million had been given away to the Iraqi government, including tanks and trucks to office furniture and latrines. Unfortunately, many items were unaccounted for.

In one year alone, over 2.4 million pieces of equipment worth a total of $250 million had been given away to the Iraqi government, including tanks and trucks to office furniture and latrines. Unfortunately, many items were unaccounted for.

The natural solution to this problem is automation; however, automation depends on solid IT structure. The best-laid plans for system data collection and automation will fall short if a network cannot realistically communicate with individual sensors and interfaces. All components of an IT network must function as one to provide a clear, crisp image of overall supply chain asset location, movements and planned deployments or shipments.

The natural solution to this problem is automation; however, automation depends on solid IT structure. The best-laid plans for system data collection and automation will fall short if a network cannot realistically communicate with individual sensors and interfaces. All components of an IT network must function as one to provide a clear, crisp image of overall supply chain asset location, movements and planned deployments or shipments. and resources in potentially hostile territories upon withdrawal from times of war, military forces need a way to gain accurate, real-time visibility and accountability into their logistics’ networks.

and resources in potentially hostile territories upon withdrawal from times of war, military forces need a way to gain accurate, real-time visibility and accountability into their logistics’ networks.